Unlock the Editor’s Digest for free

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Saudi Aramco, the world’s largest oil company, is to expand its investments in lithium production in the race to build a supply chain for the metal vital for batteries to power electric cars.

China controls about two-thirds of the market in lithium processing, but an increasing number of western and Middle Eastern companies are investing in developing their own supply chains.

The company aims to commercially produce the metal in a joint project with state-owned mining company Ma’aden by 2027 as part of broader moves to become a mining hub and diversify from oil.

“We expect that this partnership will leverage the world’s leading upstream enterprise . . . with a view to meeting the kingdom and potentially the world’s projected lithium demand,” Nasser al-Naimi, Saudi Aramco’s president of exploration and production, said in a statement.

The company said lithium demand in the kingdom is expected to grow 20-fold between 2024 and 2030, contributing to an estimated 500,000 electric vehicle batteries and 110 gigawatts of renewable energy sources.

The country has plans for lithium refining and exports, industry and mineral resources minister Bandar Alkhorayef told the Financial Times earlier.

“Saudi Arabia is very well positioned in processing because of the mixture that we have, starting from energy competitiveness, great infrastructure in terms of industrial cities and ports,” he said.

Although a brutal downturn in lithium prices because of excess supply has made it difficult for western groups to compete with China, Saudi Arabia hopes to use its financial muscle and chemical expertise to break into a market that has potential for big returns.

Global demand for lithium is expected to surge sevenfold by 2040 owing to demand from electric vehicles, according to projections in the International Energy Agency’s Net Zero scenario.

The kingdom is building an EV manufacturing hub in King Abdullah Economic City on the Red Sea coast.

American EV maker Lucid Motors, majority owned by Saudi Arabia’s sovereign wealth fund, began assembling cars in the country in 2023.

The Public Investment Fund (PIF) plans to launch its own EV brand and signed with Hyundai to build a facility in King Abdullah Economic City.

The kingdom also wants to expand its mining and metals sector as part of larger plans to diversify the economy from its dependence on oil revenues.

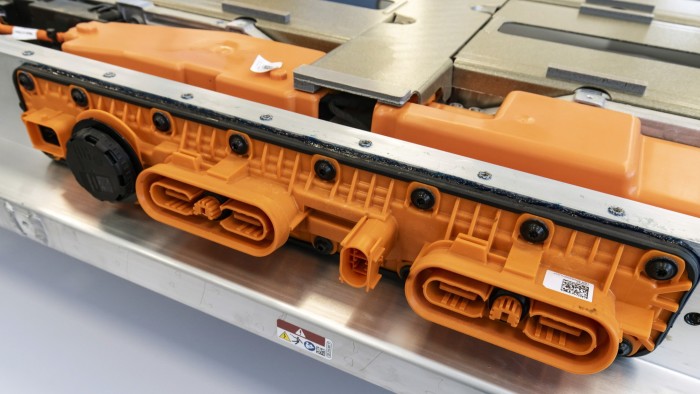

Last month Saudi Aramco, Saudi lithium start-up Lihytec and state-owned miner Ma’aden announced the country’s first successful extraction of the mineral from oilfield brine.

The mineral is widely found in the Earth’s crust, but it is also present in the brines that accompany oil production.

“We’ve not really seen Saudi Arabia play much of a part in the battery raw materials or lithium space generally so far,” said Daisy Jennings-Gray, head of prices at data provider Benchmark Mineral Intelligence.

The challenge for new lithium projects, she said, is that they need to be vertically integrated, where the producer has control over the raw materials, distribution and sales to be economically viable.

Two lithium processing facilities are in the planning stages in the country.

European Lithium announced in 2023 that it would build a lithium hydroxide facility in Saudi Arabia, together with the Obeikan Investment Group, which will process lithium rock mined in Austria.

EV Metals Group is also planning a lithium facility in Yanbu Industrial City, backed by private equity firm RCF.

ExxonMobil and Occidental are both working on lithium development and Norway’s Equinor last year bought a 45 per cent stake in two US lithium projects.

Energy companies have been a natural fit for developing lithium production from brine because many of the core skills used to produce oil, such as pumping, processing and reinjecting fluid underground, are key for producing the mineral.

Some oilfield brines, which are produced alongside oil and gas, are naturally high in lithium.

However, the technologies for extracting lithium from those brines, known as direct lithium extraction (DLE), are still nascent and have not been proven at commercial scale.

Read the full article here